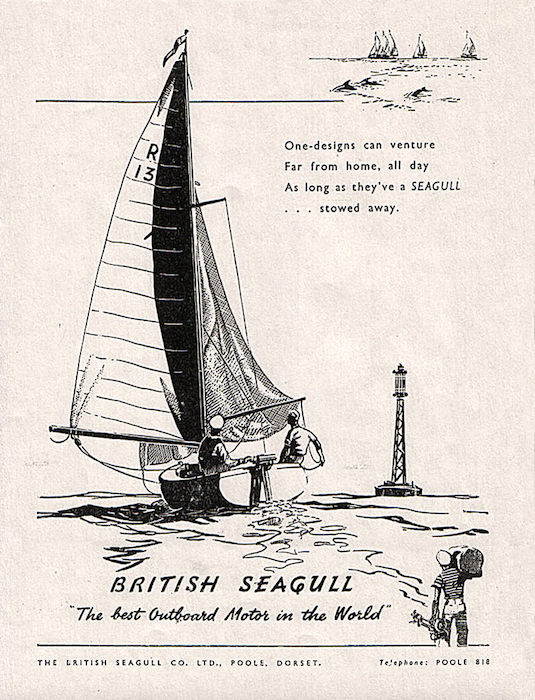

The Seagull Engine

British Seagulls were first built in the 1930s and soon settled into a design that remained fundamentally unchanged for another 50 years. There were two engine blocks: a 64cc block used for the ‘Forty’ models, producing between 1.5 hp and 3 hp, and a 102cc block used for the ‘Century’ models that developed between 4hp and 6hp. The range of horsepower from just two blocks was due to different carburettor sizes, gear ratios and propeller diameters.

A few engines had neutral gears, although you gained the impression from the maker’s literature, they viewed this as a concession to the weak minded, a true sailor having the skill to stop an engine by running the carburettor dry while stemming the tide and picking up a mooring in one go.

The basic, no-frills Seagulls have always had the advantage of being easy to repair and – for old engines – relatively reliable. Because they were designed to power displacement boats by turning a large propeller at slow speeds, bearings could be solid bronze bushings instead of needle rollers. Ignition timing and carburettor settings are fixed. An adjustable spanner and screwdriver hopefully are sufficient to carry out most maintenance. The mixing of oil with the two-stroke fuel ensured every part of the engine and its surrounds would be well coated against corrosion.

My Seagull engine was acquired Aug 2018

- GF 273HH 8

- Plug gap 0.35mm

- Fuel one part oil to 25 petrol

- Tank capacity 4 pints (2.27 lts)

- Manufactured Aug 1978

- Series 'Forty'

- Model 'Featherweight'

- HP 1 -2

- Ignition - Wipac MK2

- Gear Oil SAE or EEP140

- Model Featherweight /Bing Carb (must run 25:1)

A 25:1 mix can be achieved by mixing fuel in the following ratios: metric 40ml 2 cycle oil to 1 litre petrol. Or 5 ltrs to 0.5 litres of oil

Starting up procedure.

Open the tap at the base of the fuel tank, give the motor a shake from side to side as a warning to show who's in charge here.

Speak firmly but don't shout at it as it will take offense and refuse to start. Open the breather screw in the middle of the filler cap. You may still need to hold down the button on the float chamber to fill the carburettor.

With the choke flap in and the throttle open, wrap the rope around the flywheel slot and pull hard.

Try this several times and if still not firing, use the cord to whip the engine (see Basil Fawlty).

If the engine doesn’t start, open the choke and keep trying. After that pull out the spark plug as it probably now needs a clean and a firm talking to. Try pulling the engine over a few times with the plug out.

Still not working? Kick the nearest dog. Swear and heap curses on all 2 stroke engines. Shake your fist angrily at the heavens. Meanwhile things have probably dried out and the 'Combustion God' will have smiled on you

A good old squirt of WD40 often has the similar effect as a wet sponge on an injured rugby player.

When running there should be a steady stream of water coming out of the hole in the cylinder head at anything over idle speed. Look to see that nothing is working loose, especially the clamps on the mounting bracket. A small boat will always go faster if it is running level, so if you need to sit forward.

If you can, stop the engine by closing the fuel tap and letting it run on as you drift to a halt otherwise the carburettor will dribble fuel everywhere when the engine is tilted.

Like all two-stroke engines, Seagulls are not the most environmentally friendly motors although you could argue that keeping a 40-year-old machine running is better for the planet than buying a new one that’s unlikely to last more than ten.

Links

The ultimate place to go - Saving Old Seagulls

Good article in a good magazine (Classic Sailor)

Misc

Classic gear oil 2 stroke EP140 GL4 (£11 1 ltr)

To check the gear oil level, lay the outboard on its side with the tank side up.

Remove the filler plug.

The correct gear oil level is at the bottom of the filler hole.

To make sure the level is correct, stand the engine upright and allow any excess oil to drain out before replacing the filler plug.

Do NOT over fill.

Spark plug Champion D-16. A Mk3 Wipac ignition, then your gap must be no less than .035"

1

2